Due to the models for engine analysis usually being complex, our strategies are geared towards maximum efficiency. The following aspects should be emphasized:

- significantly shorter computing times than you would expect or that you are used to (we are up to the challenge: info@intes.de),

- Shorter computing times mean reducing costs for both software and hardware, quicker product cycles, more variation, better knowledge on behaviour of specific parts and improved products.

- Contact algorithms designed for big and complex models,

- Calculation times of non-linear sealing elements similar to linear models due to specialised solvers allowing for automatic condensation,

- Acceleration of variant analysis and optimization owing to preconditioned contact solvers,

- extremely fast thanks to PERMAS HPC fundamental technology, such as contact analysis, parallelization, and GPU-usage.

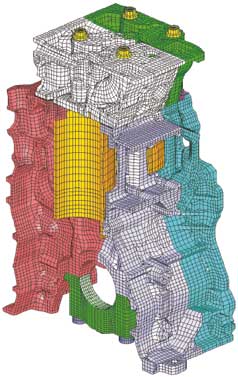

1 1/2 cylinder engine model (hex mesh)

1 1/2 cylinder engine model (hex mesh)

Gasket with pressure result

Gasket with pressure result