PERMAS-CA Contact Analysis

Contact boundary conditions may be present between elastic bodies or between elastic bodies and a rigid counterpart. The bodies may behave also non-linearly.

PERMAS provides comprehensive capabilities for contact analysis:

- Basic functions for contact in a linear or nonlinear environment (see below on this page).

- Extensions to improve performance for larger models with and without friction (see Contact with Friction).

- Update of contact geometry due to displacements in a linear or nonlinear analysis (see Contact Update).

- New solver using contact multi-grid method for essentiell runtime reduction of larger contact models (see Contact Multigrid).

The direction of contact and the initial gap width may be specified explicitly or determined automatically from the geometry. Any press fit is easily modeled by the specification of a negative gap width.

Coupling under torsional load, growing slipping regions (red)

with increasing load (by courtesy of Voith Turbo)

Methods to describe contacts

- general surface-to-surface contact (incompatible meshes).

- assignment of nodes / node sets to surfaces (incompatible meshes).

- Surface/node to ground

- Surface selfcontact

- by specification of node sets for each contact zone (the node pairs are detected automatically).

- by specification of the contact nodes in pairs.

Visualisation of contact definitions in VisPER

Load History

- The specification of a load history allows the correct simulation of assembly and working loads and any contact situation with slipping and sticking friction. This facilitates the convenient simulation of such situations in a quasi-static analysis. A postscript plot file of the load history can be exported to view its graphical representation.

- The load history can be amended by pretensioning (e.g. of bolts), where the contact analysis is used to describe the pretension. In this way, the screw tightening torque is modeled by a known contact force in the barrel of the bolt.

Pretension

A generalized concept for bolt pretension is provided. Beside the classical approach using a cutting plane with pretension in normal direction, a new approach using cylindrical thread coupling with pretension in axial direction is available. This highly innovative feature offers a convenient definition which can take into account the detailed effects of radial spreading and axial torque caused by the threads flank and pitch geometry without the need of modeling the flank shape or thread line explicitly. See bolt loosening for an advanced simulation.

Press fit connections

A pressfit is a permanent coupling with load variable interference, i.e. a variable overlap of the load history definition. It may be used as a replacement of a contact definition for permanent coupling.

Solution scheme

The analysis procedure uses a reduced flexibility model which is derived from the set of contact degrees of freedom. This procedure has the following advantages:- The iteration is very efficient making it best suited for extremely large models with an arbitrary number of contact nodes.

- The accuracy of the results is fully preserved, because no additional stiffnesses are introduced by the modeling of contacts.

The simultaneous analysis of an arbitrary number of loading cases is possible. The contact parameters, i.e. gap width and coefficients of friction, may be different for each

loading case. The contact boundary conditions are taken into account automatically by the static analysis procedure.

No additional user request is required for a contact analysis.

For efficient calculation of successive contact variants contact status files are available for easy job recovery and considerable run time reductions.

Further information can be found in the lecture "Next Generation Contact Analysis" . You can also watch this lecture conveniently on YouTube .

Contact Results

Comprehensive checks allow the verification of contact models like type of contact, its geometry (gapwidth and normal vector), and the contact coordinate system (for normal and frictional force directions). In addition, the contact status is available in all iteration steps for checking purposes.For frictional contact the quality of surfaces is of utmost importance. Therefore, PERMAS can smooth contact surfaces in order to essentially improve frictional behavior.

In addition to all results usually derived from a static analysis the contact analysis provides for the contact status, the contact forces, the contact pressure, the gap widths, and the relative gap displacements.

The center of pressure concept may help to derive a better understanding of the force transmission in contact problems.

Contact pressure and gasket closure result

Contact locking

For subsequent analyses, contact states can be locked. This contact locking leads to linear constraints according to the current contact state. To achieve this, the active contacts are automatically transformed into kinematic constraints. With this new model various kinds of subsequent analyses are possible like eigenvalue analysis DEV, heat transfer analysis HT, or submodeling).

Ball-bearing

Conical press-fit with all-slipping friction

Contact and Friction

Solvers for ambitious slip-stick problems and solution algorithms for larger contact models (more than 10,000 contact node pairs) in order to essentially accelerate contact analysis runs again (by a factor of 3 and beyond), e.g. performance breakthrough. The functionality comprises the following features:

- High performance iterative solution algorithms to accelerate standard contact analysis with normal and frictional contact, see, engine analysis.

- An additional very stable iteration method for critical slip-stick problems (when all contacts get into sliding state, see figure).

Gasket elements are handled as integral part of the contact iteration through contact controlled nonlinear gasket analysis (CCNG analysis) by default. This leads to a remarkable reduction of run time compared to the classical solution method with nonlinear material behaviour. In particular, this run time reduction will be much higher, when the nonlinear features are contact and gasket elements only. The run time reduction is still significant, if additional nonlinearities are applied.

For sliding friction between dynamically moving parts a velocity field can be prescribed to take it into account in a quasi-static contact analysis (see Brake Squeal Analysis).

Shaft-hub connection with friction, change of the

contact status (read: sliding, blue: sticking)

Contact Update

In case of large relative displacements of two bodies in contact, the update of the contact properly reflects the change of the relative position of both bodies.

If very accurate contact results are required, contact updating even reflects very small changes of the contact geometry which gives exact contact forces, displacements, stresses, etc..

Features:

CV Joint with center of pressure visualization

Drive gear and crown gear.

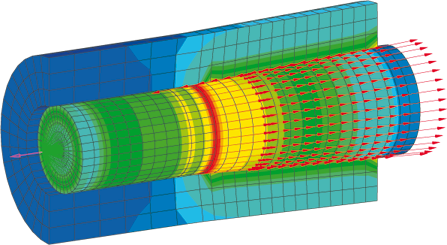

Contact Multigrid Solvers

The algorithms provide a new generation of contact solvers in order to enable the solution of complex contact problems with extremely short runtimes. The solvers use innovative update schemes for the flexibility matrix, as well as a new contact-multigrid coarsening scheme (see picture on the right) to reduce runtime complexity.

The approach realized in PERMAS is based on a problem reduction by condensation, instead of a problem extension by the contact dofs (condensed lagrange flexibility solution). Thus, this is a true technology alternative to the mainstream approaches. See also WebConference. INTES has about 30 years of experience with this kind of technology. Further informations see Presentation.

The contact multigrid solver (CAMG) is an opportunity to further scale up the structural mechanics model size as well as the contact dofs.

The resulting perfomance gain may be used to analyze model variants, or in combination with structural optimization.

The functions may be used with linear statics (LS),

or with nonlinear statics (NLS).

Some properties:

- Easy-to-use: No changes in dat/uci files needed.

- Numerically equal results.

- Significant performance improvements for contact (up to > 20).

- See subsequent examples.

Speedup of motor simulation with gaskets and temperature dependent material data

Computation times are given as elapsed time [hh:mm]. Speedup (green) for total job and contact computation.

Application example, courtesy of PORSCHE AG

Speedup of gearbox calculation

Computation times are given as elapsed time [hh:mm]. Speedup (green) for total job and contact computation.

Gearbox calculation (model similar, courtesy of ZF Friedrichshafen AG)

Three generations of contact solvers

Principle: coarsening and projection