- significantly shorter computing times than you expect and know (we accept your challenge: info@intes.de),

- get lower software costs, lower hardware costs, faster product cycles, more variants, better knowledge of the component behavior and better products through shorter computing times,

- Contact algorithms designed for very large models,

- Complex Eigenvalue Analysis with (CEA) true frequency damping,

- Acceleration for variant analysis and optimization through preconditioning of the contact solver,

- Integrated sampling for the parameter variation of all important parameters and additional specialized sampling algorithms for the coefficient of friction, whereby the variation requires hardly any additional runtime with a lot of additional knowledge about the component behavior,

- Optimization for brakes: topology, parameters and shape,

- Squeal reduction through optimization: parameter and shape optimization,

- continuously new developments for brake calculations, new methods also in the next version of PERMAS.

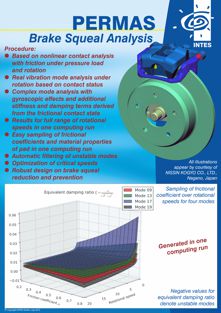

Brake Squeal Analysis with PERMAS

Brake squeal is a known phenomenon since brakes are used, and despite

intensive research for many decades there are still coming new cars to the market which are squealing so heavily that expensive warranty cases arise for the manufacturers.

This holds not only for passenger cars but also for commercial vehicles, the same for rail cars or aircraft brakes or even bicycles.

Also, not only disk brakes but also drum brakes and clutches are affected.

Benefits and particular strengths

Overview

There is no lack of numerical approaches to make brake squeal computable but up to now the complexity of the phenomenon has prevented

massive computations in this field due to very long computing times.

As long as one set of parameters for one brake requires many hours of computing time, it is practically impossible to study geometrical

modifications to get a configuration which does not exhibit squealing under all typical operating conditions.

Brake squeal is widely understood as friction induced dynamic instability. Therefore, two principal approaches are available: Transient analysis and complex eigenvalue analysis. Due to high computational effort for transient analyses obviously stability is more effectively studied by a complex mode analysis.

The analysis can be split up in following steps:

A complex mode analysis is performed in one computing run for the full range of interesting rotational speeds. By this sweep all relevant points of instability are obtained for one set of brake parameters. Successive computing runs are then used to study parameter modifications in order to establish a stability map for all important influencing effects.

Brake squeal is widely understood as friction induced dynamic instability. Therefore, two principal approaches are available: Transient analysis and complex eigenvalue analysis. Due to high computational effort for transient analyses obviously stability is more effectively studied by a complex mode analysis.

The analysis can be split up in following steps:

- A linear static analysis with contact and friction under brake pressure and rotation. There, sliding between disk and brake pad can be prescribed by a rigid body motion to determine the sliding velocity.

- A real vibration mode analysis using the previously calculated contact status. This requires a linear model for the contact status with frozen contact status.

- A complex mode analysis with additional frictional and rotational terms. Gyroscopic and stiffness terms are taken into account which consider the disk as elastic structure in an inertial reference system. Additional stiffness and damping terms are derived from the frictional contact state perviously calculated in the contact analysis.

A complex mode analysis is performed in one computing run for the full range of interesting rotational speeds. By this sweep all relevant points of instability are obtained for one set of brake parameters. Successive computing runs are then used to study parameter modifications in order to establish a stability map for all important influencing effects.

Simple brake model (1) with an unstable

bending mode(m=2, n=1) at 2,54 rps

Questions? Ask us!

INTES Ingenieurgesellschaft für technische Software mbH

Management: Rolf Fischer

Breitwiesenstr. 28

70565 Stuttgart

Germany

Commercial register: Stuttgart HRB 10 978

VAT registration number: DE 147803245

Tel.: +49 711 78499-0

✉info@intes.de